Through the development of the SERAC® electric cylinders, all the technological advantages of an ASCA® servo spindle can be utilized in a series-produced complete solution.

This makes super compact designs with high power density possible for space-limited applications. Due to the high control quality of the play-free ASCA® servo spindle, applications with very short cycle times can be realized.

Thus, SERAC® electric cylinders offer a clean alternative to hydraulic cylinders for many applications. With the typically slim design of the SERAC® electric cylinders, it is often possible to replace hydraulic cylinders even in existing constructions.

The direct drive of the ASCA® servo spindle (without an additional reduction gearbox) and the smooth movement without rolling back lead to a number of special unique selling points.

Unique selling points

Highest power density through small spindle pitches from 0.5 mm

The spindle pitch can be adjusted to the respective application

Direct drive of the ASCA® servo spindle without an additional gearbox, resulting in good controllability and high dynamics.

High durability due to the use of a heavy-duty spindle drive with many power transmission points

Integrated linear displacement measurement system for the highest positioning accuracy under load

Low noise development due to the use of a spindle drive without roller reset.

Interpretation and manufacturing of all PWG components in-house

What SERAC® electric cylinders are available?

SERAC® XH

The sleek design closely resembles a hydraulic cylinder, so that in many cases switching to electric drive is associated with little constructive effort.

SERAC® KH

High-stiffness construction with stable torsion protection in a super-compact housing. Front and side mounting options for individual installation.

SERAC® LHP

The completely modular design characterizes the LHP series. The implementation with a hollow shaft motor and a directly driven spindle nut allows for long strokes to be realized in this very compact electric cylinder.

SERAC® XHM

The technological structure of this spindle unit with integrated guide corresponds to the SERAC® XH electric cylinder. Designed for the attachment of any servo motors.

SERAC® XH

Compact electric cylinder

Super slim design with optimal dynamic behavior as an ideal replacement for hydraulic cylinders

Maximum strength 4.5 to 12 kN

Well suited for highly dynamic applications (accelerations of up to 26.5 m/s² possible)

Low moment of inertia due to drive via spindle rod

High regulation quality for fast positioning

Achieving the shortest cycle times

Integrated twist protection for smart constructions

End switch directly mountable on cylinder

Optional available with parking brake

Compatible with servo controllers from various renowned manufacturers

SERAC® LHP

Modular construction

In addition to the basic explanations, all options can be selected in combination:

Maximum force 10 to 100 kN

Slim cylindrical design

Rigid construction

Torque protection, holding brake, integrated linear position measurement optional

Small incline also feasible at high forces

End switch directly mountable on cylinder

Compatible with servo controllers from various renowned manufacturers

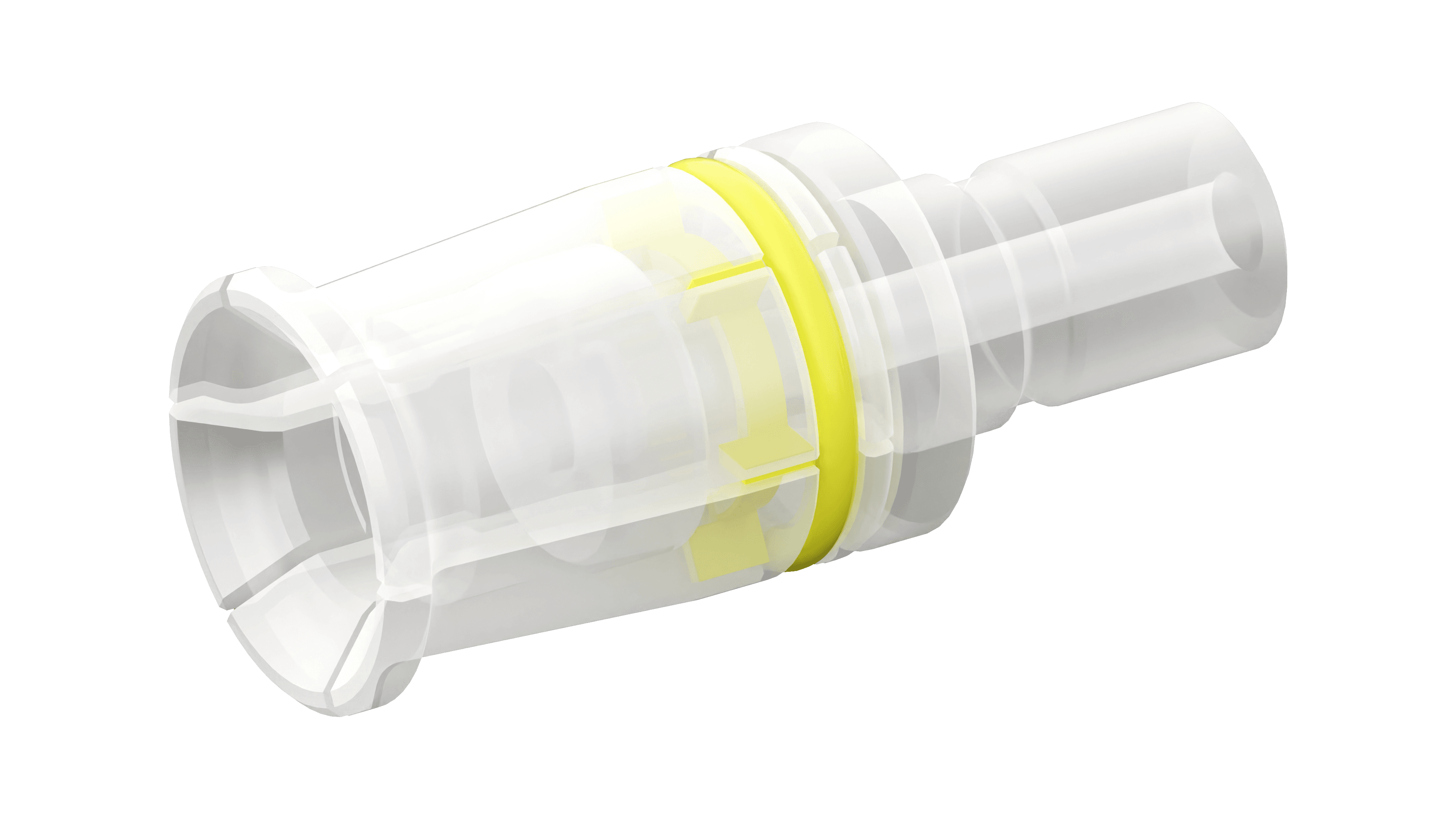

SERAC® KH

Super compact for short strokes

All components of this ready-to-install complete drive are housed in this fully smooth-surfaced housing.

Maximum force 4.5 to 30 kN

High-stiffness construction

Stable Leadership

Very short construction length

Side mounting options or flange mounting for individual installation

Heat sink for liquid cooling (optional)

Ideal applications: punching and sheet metal processing

Direct path measurement for highest positioning accuracy under load

Compatible with servo controllers from various renowned manufacturers

SERAC® XHM

High-stiffness spindle unit for customer-side motor mounting

The technological design of this spindle unit with integrated bearing corresponds to the SERAC® XH electric cylinder. Industry-standard servomotors can be attached using an adapter flange and coupling.

Maximum Force 400 kN

Spindle pitches from 1 mm

High stiffness

Integrated direct path measurement

No game

Long lifespan

Torsion stiffness servo coupling

Adaptation option for numerous engine manufacturers

ServoOne® by KEBA

High-Performance Controller

Servo control for unrestricted use of the specific dynamics of SERAC® electric cylinders

Two series allow for customized solutions: The servo controllers from the ServoOne and ServoOne junior series are used.

High-speed communication through common field bus interfaces such as Profibus, EtherCAT®, SERCOS II & III, PROFINET IRT, CANopen® ...

High-performance control for precise and dynamic linear movements

iPLc can be optionally integrated into IEC 61131 for quick adaptation to the specific application with direct access to the drive controller peripherals.

Integrated functional safety through standard STO (Safe Torque Off). Additional functions are optionally available.

Compact design for optimal use of the control cabinet