Ortlieb HSK clamping tools form the basis for the safe and reliable tensioning of HSK tools. The use of ceramics on the functional surfaces – in combination with a wear-resistant hard coating – makes it possible for the first time to offer a completely maintenance-free tool clamping set.

This ensures a constant clamping force over the product lifetime of up to 3 million load cycles.

The permissible clamping forces are up to 200% (HSK A50) higher than the minimum clamping forces recommended by the standard DIN 69893/69063. This ensures secure clamping of the tools even under higher loads and speeds.

With well-thought-out assembly tools, the Ortlieb HSK tool clamping sets can be assembled or replaced in no time.

They are available in two product lines: ToolGrip® HSK and UniGrip® HSK.

ToolGrip® HSK

tool clamping sets

The ToolGrip HSK tool clamping sets were specially developed for high-speed cutting (HSC) and heavy milling operations.

Allows for much higher clamping forces than the minimum clamping forces recommended by the standard DIN 69893.

This clamping set impresses with its short construction length, its simple, maintenance-friendly design, the large coolant passage, and the high clamping forces.

The vulcanized 6-part clamping fingers are designed for a product lifespan of 2 million load changes.

All spacing sets are available in wear-resistant coated versions upon request.

ToolGrip® HSK with holding function

tool clamping sets

For shorter switching times and faster tool changes

Special clamping set with holding function

This keeps the released tool in the machine spindle until it is pulled out by the tool changer.

Tension sets with varying holding power available on request

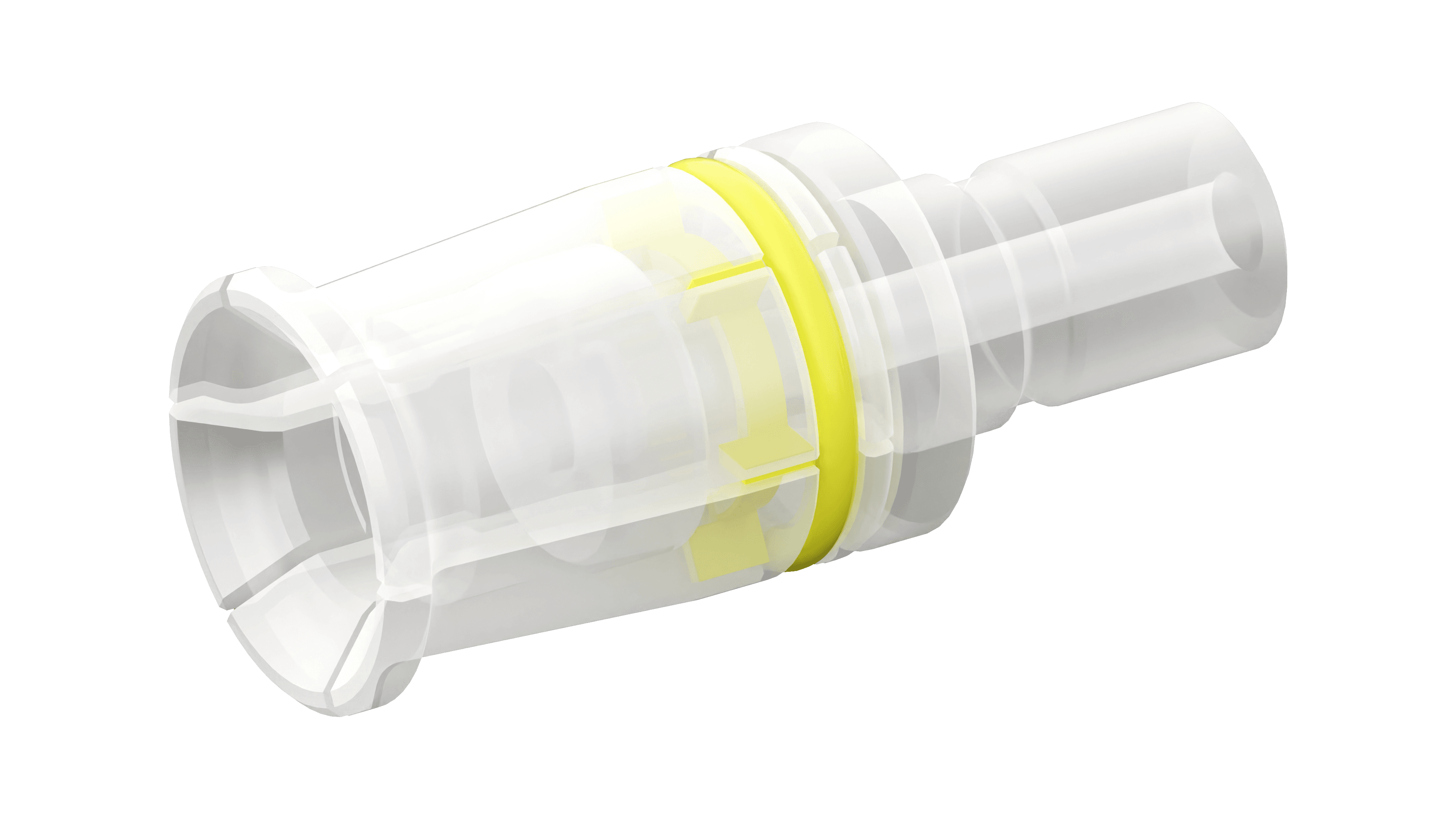

UniGrip® HSK

tool clamping sets

Enables maximum speeds of up to 40,000 min-1 with increasingly high clamping forces

The UniGrip HSK tool clamping set consists of the pull bolt, 8 individual clamping fingers, and a spring return mechanism that holds the clamping fingers in position.

Available in coated, wear-resistant version as well as in ceramic or durable version.

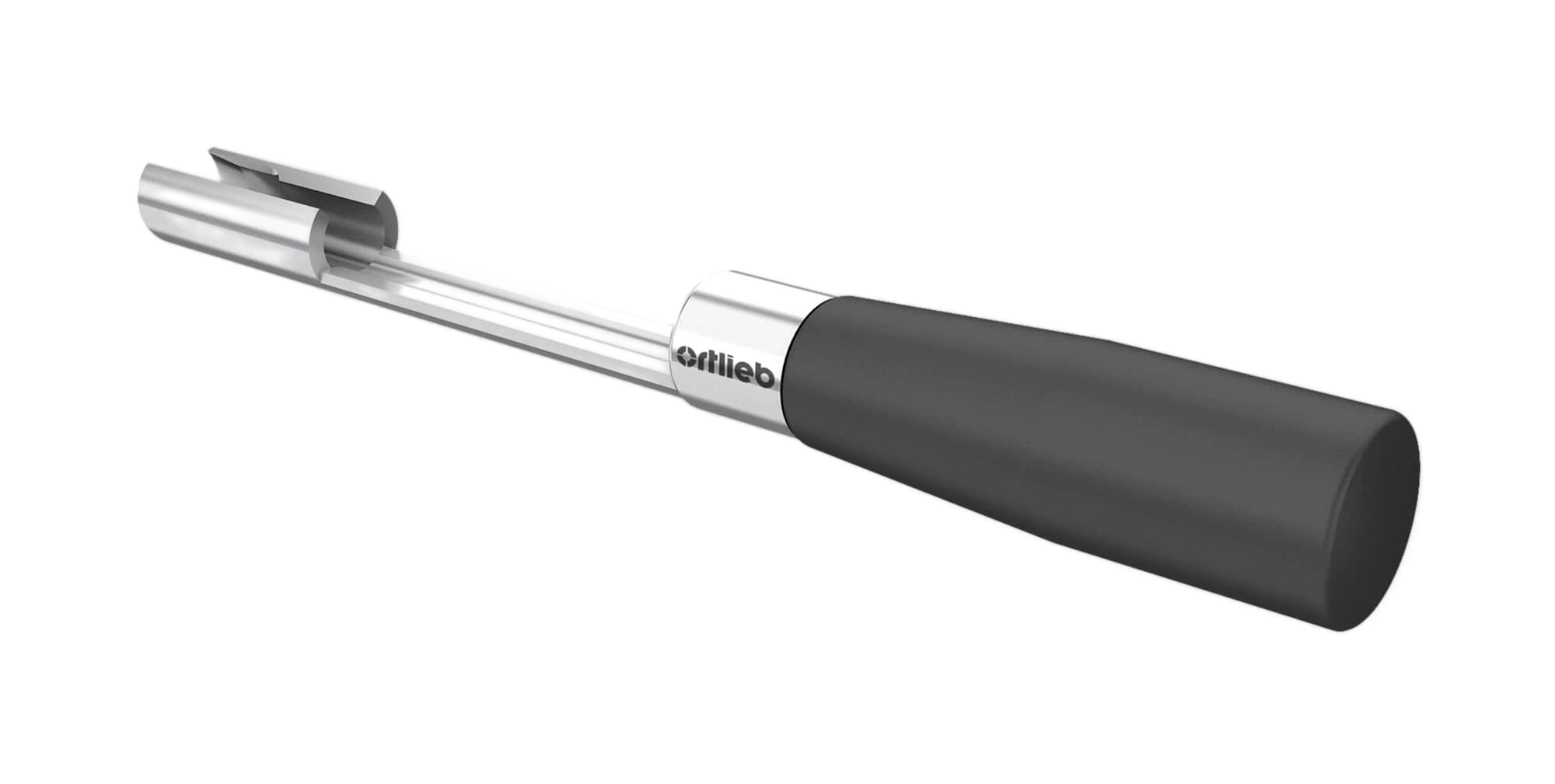

MoFix® WGM 48-05

Mounting device

Enormous relief of the assembly - especially with a vertically standing machine spindle.

After installing the spring return mechanism, the MoFix® is screwed onto the thread of the adjusting rod.

Subsequently, the individual tension fingers can gradually be inserted into the machine spindle.

This not only simplifies the assembly but also significantly reduces assembly times.