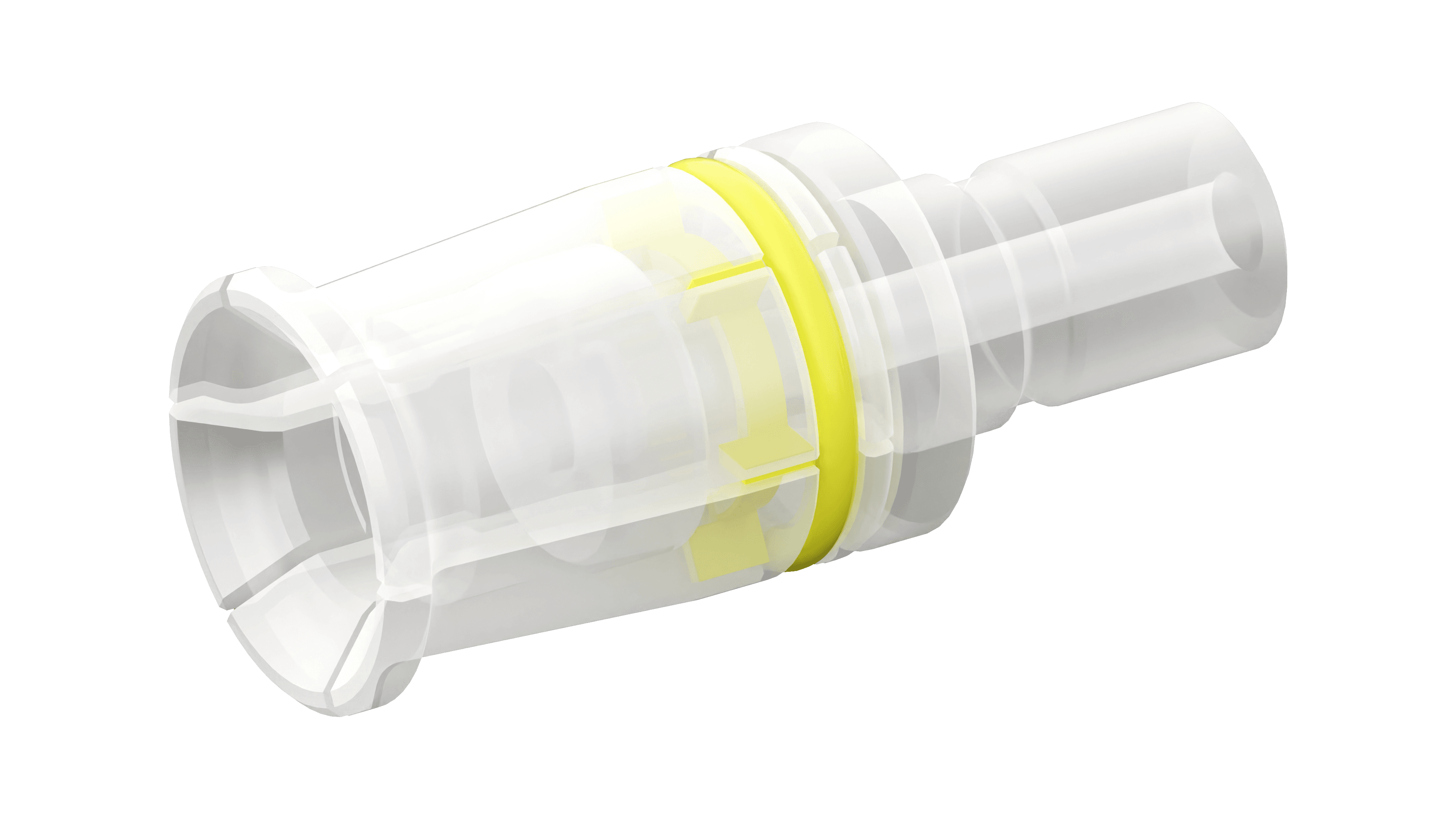

The internal tensioning system CenterGrip® operates without a tension screw, allowing for bag holes to be tensioned down to the bottom.

The 6-segment expanding sleeves (CG30 = 3 segments) are based on the proven Rubber-Flex® vulcanization technology and offer a maximum clamping length of 51.5 mm with a step size of the clamping diameter of 1 mm. Deviations in clamping diameters and contours are available upon request.

Another special feature of the clamping system is the large clamping tolerance of ± 0.6 mm to the nominal diameter. Thanks to the quickly interchangeable stops and the bayonet connection of the clamping sleeves, the system can also be quickly and easily converted when changing workpieces. Four different, compact base clamping mandrels cover a clamping range of 18–135 mm with the help of corresponding clamping sleeves.

The workpieces are reliably pulled against the stop due to the downforce effect, which can optionally be executed with a single-circuit air system control for a secure automatic workpiece change.

Your benefit:

Short setup times thanks to expansion sleeves with quick-release closure

High roundness accuracy ≤ 0.015 mm possible

Span tolerance nominal diameter $ 0.6 mm (CG30 ÷ 0.4 mm)

Compact design, resulting in a reduced disturbance contour

Optional with circular air system control for automatic workpiece change