Innovation made by Ortlieb: With VarioLine® we bring electric drive technology into clamping technology, enabling a variety of Industry 4.0 applications.

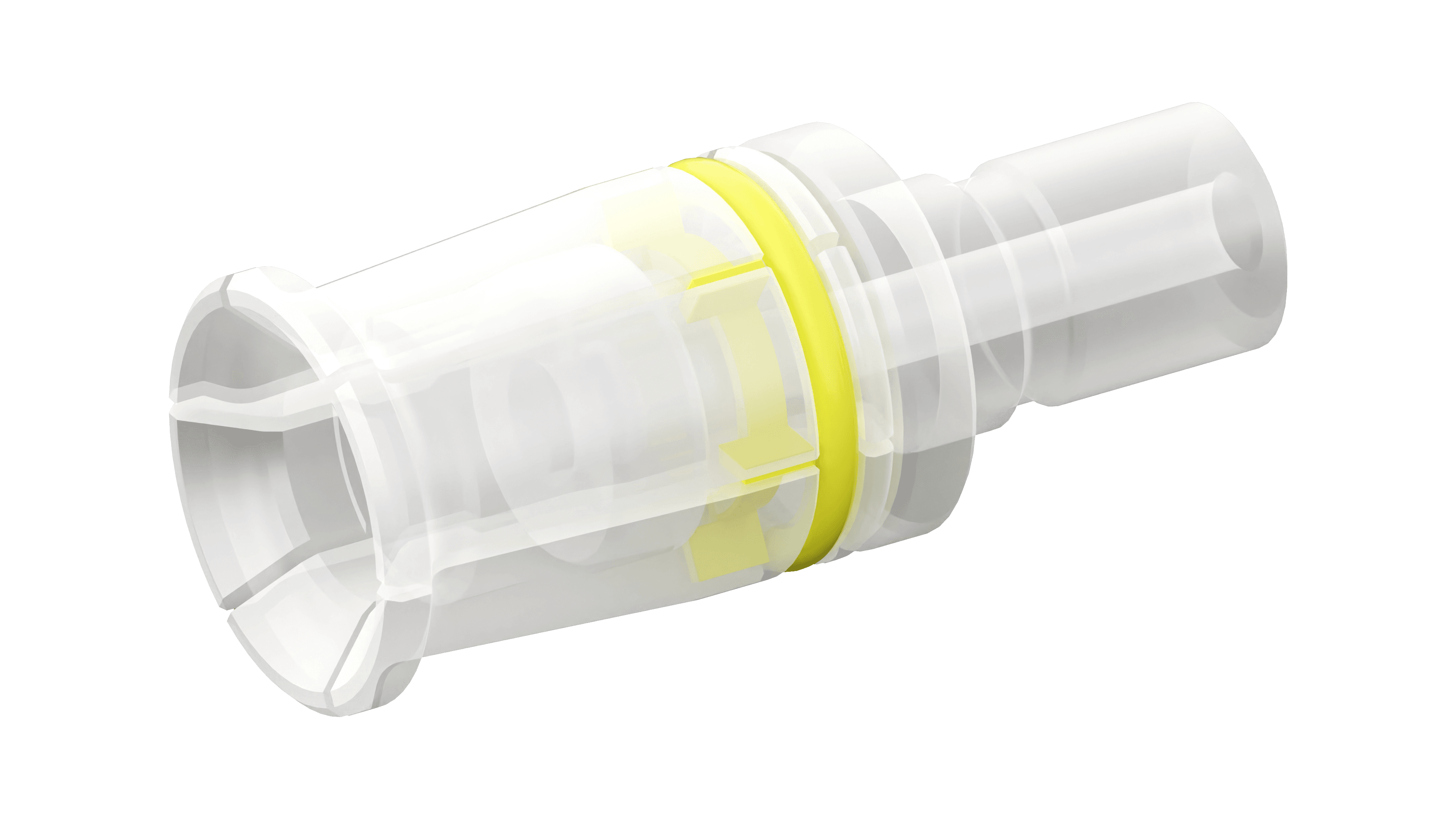

The dimensions of the ASCA servo spindle can be designed to be extraordinarily compact in relation to the achieved force. Since the reduction function of a planetary gearbox is part of the functionality, the motor connection can be made directly without an additional gearbox.

With its compact dimensions and the ability to achieve very high forces and fast movements with small motors, the ASCA servo spindle aligns with the mechatronics trend towards compact, efficient solutions.

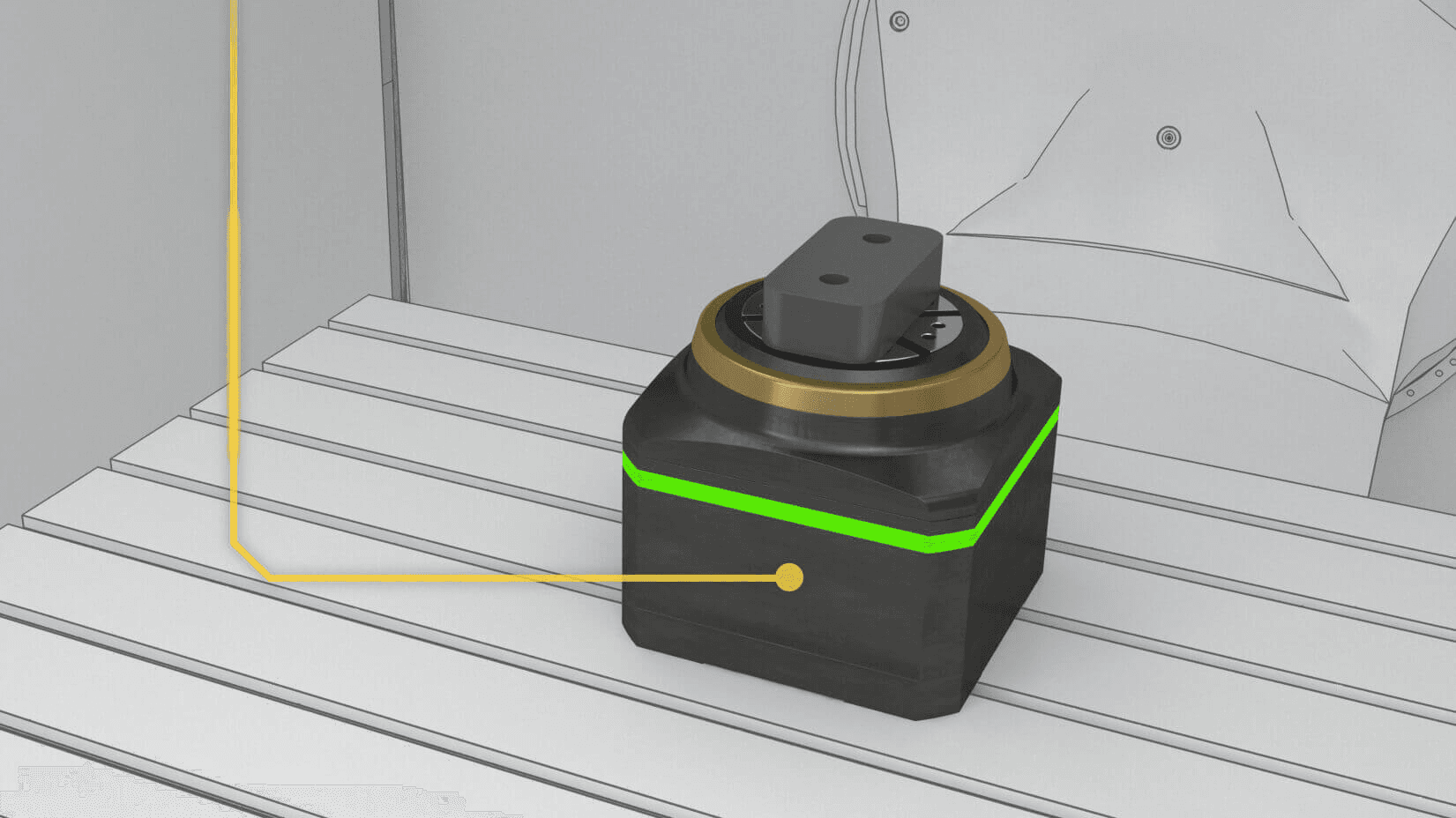

Stationary operation

The electromechanical clamping unit Ortlieb VLe is excellent as a clamping tool for the stationary clamping of workpieces in drilling, milling, and machining centers.

Mobile use

The Ortlieb VarioLine VLe can also be used for automated external loading via robots or automated pallet handling. It is ideally suited for mass production.

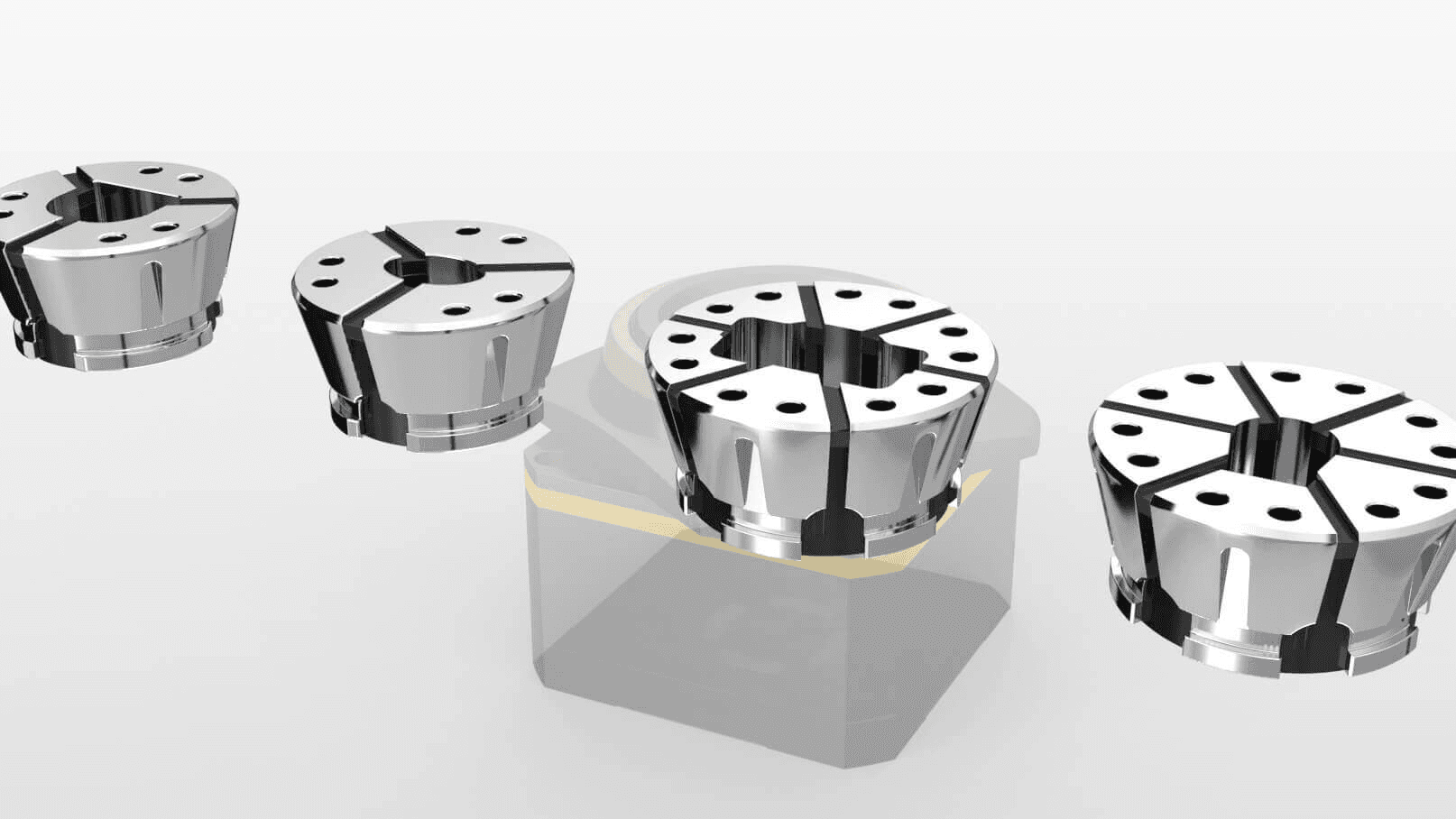

Modular external and internal clamping system

An additional feature of the VarioLine allows for the quick and easy conversion from external to internal tension. The workpiece holder and clamping element are exchanged, while the base module remains the same.

Electronically individually adjustable clamping force and monitoring of position and workpiece setup

The setup of the electronically individually adjustable clamping force and the monitoring of the clamping position is done indirectly through the current control of the servomotor or optionally via force sensors in the workpiece holder. The retention of the electronically individually adjustable clamping force is achieved frictionally through the self-locking in the planetary gear drive, even when the servomotor is turned off.

Optionally, there is the possibility to monitor and correct the electronically individually adjustable clamping force on the workpiece during the machining process via servo controllers. The position of the workpiece relative to the contact surface of the clamping device can also be checked upon request. The measurement is carried out using the inductive or capacitive sensors in the workpiece holder. Ideal conditions for Industry 4.0 integration.

Construction sizes and special solutions

The stationary clamping unit VarioLine VLe from Ortlieb is available in 3 basic sizes and 2 variants as well as various clamping ranges. Special solutions are more the norm than the exception at Ortlieb.