Automation has been established in the machining industry for many years. What started with bar feeders is now standard, for example, in complex machining centers equipped with robots: the automatic handling of untreated and processed workpieces.

For several years, we have been offering custom special clamping tools here, all of which have a common goal: to shorten processes through complete machining in as few clamping setups as possible with adaptive workpiece clamping technology.

We would be happy to adapt the workpiece clamping to your application.

Contact us!

Workpiece automation

Reference project 1

Thin-walled engine housing made of deep-drawn steel sheet

Requirement

External tension via elastic membrane element. Tension force continuously adjustable with an additional spring element.

Machine connection

Short cone 5 DIN 55026/27

Function

The feed can be adapted for different workpieces by replacing the four clamping jaws as well as the axial stop. The clamping force is initiated by the elastic membrane element. An additional spring element allows for stepless adjustment of the clamping force. It is released via a pneumatic cylinder. The membrane clamping principle ensures low susceptibility to interference and reduced risk of contamination.

Workpiece automation

Reference project 2

Forged gear hollow shaft

Requirement

Internal tension with high radial transmission forces. Dirt-insensitive design.

Machine connection

Short cone 6 DIN 55026/24

Function

Hydraulically operated clamping mandrel with pointed-toothed sliding jaws. Clamping is done via spreading bolts. After loosening, the sliding jaws are pressed back into their original position by a radial spring. Due to a precisely fitting jaw holder, the risk of contamination of the sliding components is low.

Workpiece automation

Reference project 3

Turbine blade for gas turbines

Requirement

Replaceable clamping adapter via handling system. External clamping instruction via electric screwdriver. Dirt-resistant design.

Machine connection

HSK 100 DIN 69893 modified

Function

A handling system transports the clamping adapter to the setup station. There, the workpiece is inserted into the adapter using the dovetail guide and clamped using an electric screwdriver. The handling system then transports the adapter with the workpiece to the CNC machining machine. The clamping adapter is hermetically sealed against contamination.

Workpiece automation

Reference project 4

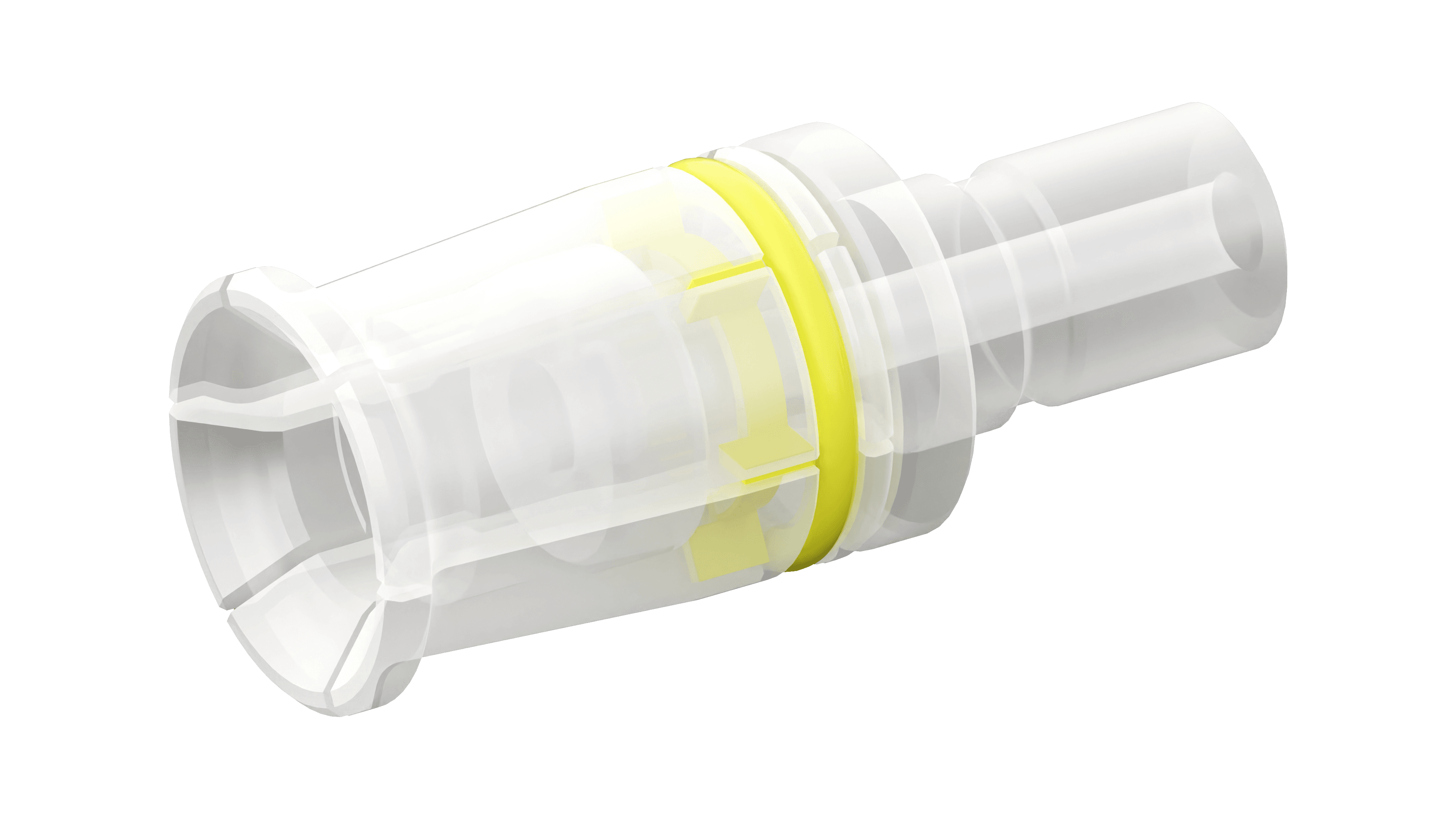

Thin-walled reduction sleeve

Requirement

Clamping on a double spindle CNC lathe for 2-sided machining. Without lowering effect, with plane setup control, clamping length 140 mm, clamping diameter 94 mm, run-out accuracy less than 0.015 mm. Dirt-insensitive design.

Machine Connection

Short Cone 6 DIN 55026/27

Function

The collet is actuated hydraulically, with the workpiece being clamped by a vulcanized Rubber-Flex collet. The collet can be quickly changed via a bayonet lock. The clamping process occurs position-neutrally. The workpiece position is monitored by the air system control. The chuck is sealed against dirt ingress.